Hey! Thanks for visiting my page!

My name's Chris and I'm a proud aerospace engineer from UCLA! In both undergraduate and graduate school I did research in Taira Lab, where I focused on modeling the flight dynamics of D90 -- a tailless unmanned aerial system (UAS). In addition to research, I've worked on a multitude of projects from designing and building RC drones to writing my own incompressible flow solver code. As you'll see when you explore this page, I love all things aerospace!

Outside of research and work, I love traveling and playing my guitar. So far, I've been fortunate to see most of the United States, Mexico, and parts of Central and South America. My next dream is to backpack through Europe - visiting Portugal, Spain, Italy, France, Switzerland, and more - before also making my way to Japan. Regarding guitar, I really enjoy writing my own music, drawing inspiration from the smooth melodic styles of artists like John Mayer and Jack Johnson.

SoCal Fluids XVIII -- Development of a Flight Dynamics Model for D90 -- April 19, 2025 | University of Southern California

In undergraduate and graduate school, had the privilege of conducting research with Professor Taira. Being part of Taira Lab was incredibly rewarding - I worked on a fascinating project alongside the most talented people I've ever met. In collaboration with Professor David Williams and Ph.D. candidate Sai Simon at the Illinois Institute of Technology, I studied the flight dynamics of D90, a tailless unmanned aerial system. Through this work, I developed accurate models of the aircraft's flight dynamics during takeoff and descent, including Dutch roll behavior.

One of the most rewarding courses I took in graduate school focused on incompressible computational fluid dynamics (CFD). As part of the class, each student developed their own solver for a lid-driven cavity flow problem with an immersed boundary. I wrote a report detailing the process of developing my solver and implementing an immersed boundary method, in which I compare different finite-differencing and time-stepping schemes, and carefully validate and verify my results.

One of my favorite courses involved designing a full-scale aircraft to meet a specific set of surveillance mission requirements. Collaborating with two teammates, we developed the "Silent Night Surveillant" - a conceptual surveillance UAV for Santa Claus. The aircraft was designed to launch from Santa's offshore "Christmas Carrier", fly to the UCLA campus, identify and monitor a student of interest for 24 hours, and return to the ship for data processing and transmission back to the North Pole.

My contributions included selecting key aircraft components such as the engine and payload, as well as developing a Monte Carlo optimization framework to determine the optimal aircraft dimensions for our mission profile. I also led development of the guidance, navigation, and control (GNC) system, implementing logic for the UAV to autonomously loiter over UCLA until the target is located, then maintain surveillance by circling the target until the mission duration is complete.

As part of a 10-person team, I helped develop the Mayfly spacecraft, designed for a sample retrieval mission. I was responsible for the spacecraft's launch vehicle and propulsion system, and collaborated closely with the mission trajectory, power systems, and thermal systems leads. We used an iterative design approach to ensure the spacecraft had sufficient power and capability to complete the mission successfully. I conducted trade studies to evaluate the feasibility of chemical versus solar electric propulsion (SEP) systems, ultimately selecting SEP. I then evaluated a range of thruster options, analyzing total system mass, specific impulse, power consumption, and thrust in the context of mission constraints to determine the optimal configuration.

In another course, I worked on a team tasked with designing and building an autonomous drone capable of identifying the optimal trajectory through a randomized set of waypoints. I served as the electronics lead, responsible for integrating all internal components to ensure stable power distribution and reliable communication across systems. Having previously built my own personal drone, I found this project both exciting and rewarding, as it allowed me to apply past lessons and improve upon earlier mistakes.

To explore rotorcraft and gain hands-on experience, I designed and assembled a 5-inch RC drone entirely from scratch. Wanting full control over the frame design, I modeled it in SolidWorks and 3D printed the parts myself. During the design process, I conducted extensive research into each individual drone component, learning how characteristics like motor KV rating and battery cell count affect flight performance under different conditions. I documented my findings and used them to carefully select and pair components for optimal performance. After assembling and configuring the drone, I test flew it and iteratively redesigned certain parts of the frame that needed improvement. I also experimented with various propellers to achieve smoother, more stable flight.

I'm currently working on getting my HAM Amateur Radio License, which will allow me to operate a video transmitter (VTX) and mount a camera on the drone. With this, I can stream real-time first-person video during flight.

During one quarter at UCLA, I led a team in designing, building, and flying a remote-controlled airplane. After selecting a general aircraft configuration, we used school-provided MATLAB code to estimate key parameters such as total weight, dimensions, and wingspan of our aircraft. Using these values, along with aerodynamic data like lift and drag coefficients, we carefully selected airfoils for the wing and stabilizers that aligned with our performance goals. We modeled and assembled the entire aircraft in SolidWorks, continually refining components throughout the 10-week quarter based on testing and performance evaluations. As we tested different assemblies, we identified and implemented design improvements that significantly enhanced flight stability and efficiency.

In the end, watching our airplane take flight and achieve record-setting performance was an incredibly rewarding culmination of our team's hard work and engineering decisions. We won the class award for designing the fastest airplane.

During another quarter at UCLA, I took part in a voluntary, hands-on rocket engineering project where students collaborated in teams to design, build, and launch two solid motor rockets. Our first rocket used a C-class motor, while the second was powered by a stronger G-class motor.

Each team member conducted independent research and contributed unique ideas to each of our designs. We experimented with different materials and iterated on our prototypes based on test results. Our first rocket was fully 3D printed, while the second incorporated fiberglass and wood to reduce weight and increase performance. After analyzing the outcome of our first launch and making key design improvements, our second rocket exceeded expectations - reaching an apogee of approximately 3,200 feet. This rocket is shown in the images to the right.

In Taira Lab, I also serve as the go-to person for 3D printing. In addition to creating educational prints for community outreach events - such as car models to insert in a small wind tunnel - I also produce 3D-printed visualizations of simulated wing flows from data provided by my colleagues.

To do this, I developed a set of MATLAB functions that convert CFD simulation data into 3D-printable models. Once the simulation data is imported, flow information is interpolated onto a fine 3D mesh grid. I remove any discontinuities in the flow and then project velocity data as color onto the surface of the generated structure. The final result is saved as a colored .obj file, ready for 3D printing.

Using my personal 3D printer, I've produced several prototypes, allowing me to fine-tune the parameters in my scripts to ensure the cleanest possible prints. This process has also helped me gain lots of experience in 3D printing, maintenance, and troubleshooting common print errors. The images to the right show completed colored models of flow simulations over both swept and straight wings.

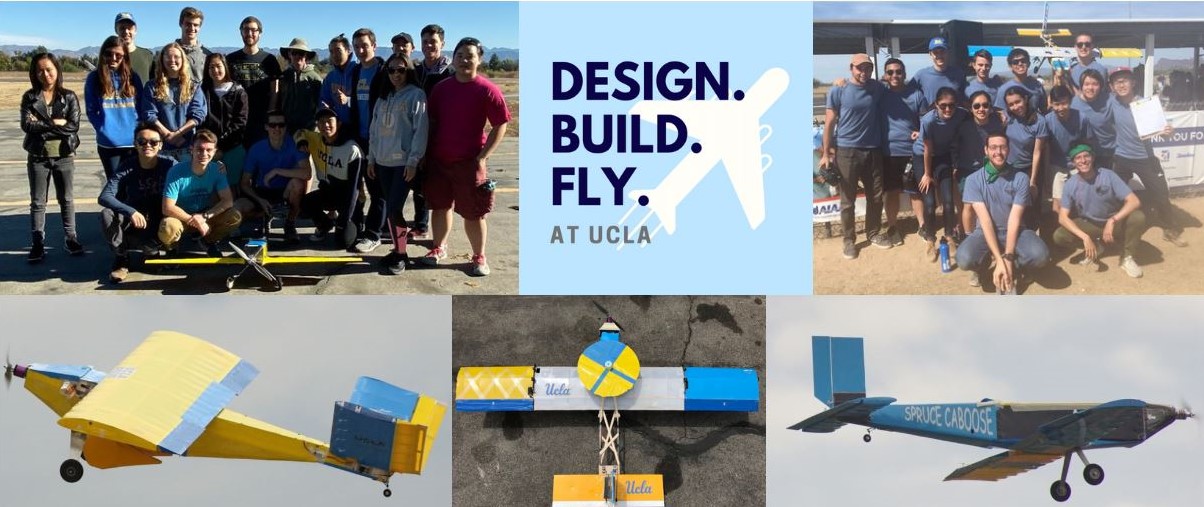

At UCLA, I joined the Design/Build/Fly (DBF) team, a student-run organization that designs and builds a remote-controlled airplane for the annual AIAA DBF Competition. I initially contributed to the aerodynamics team, using SolidWorks, SimScale, and MATLAB to run CFD simulations and analyze performance data. Over time, I transitioned to the manufacturing team, where I found the hands-on work more engaging and accessible. There, I helped with the overall aircraft design and assisted in assembling the stabilizers. Our efforts culminated in a strong performance at the competition, where UCLA placed 15th out of 81 teams - our best finish to date.